Unlocking Business Potential: Additive Manufacturing in Cambridgeshire

Introduction

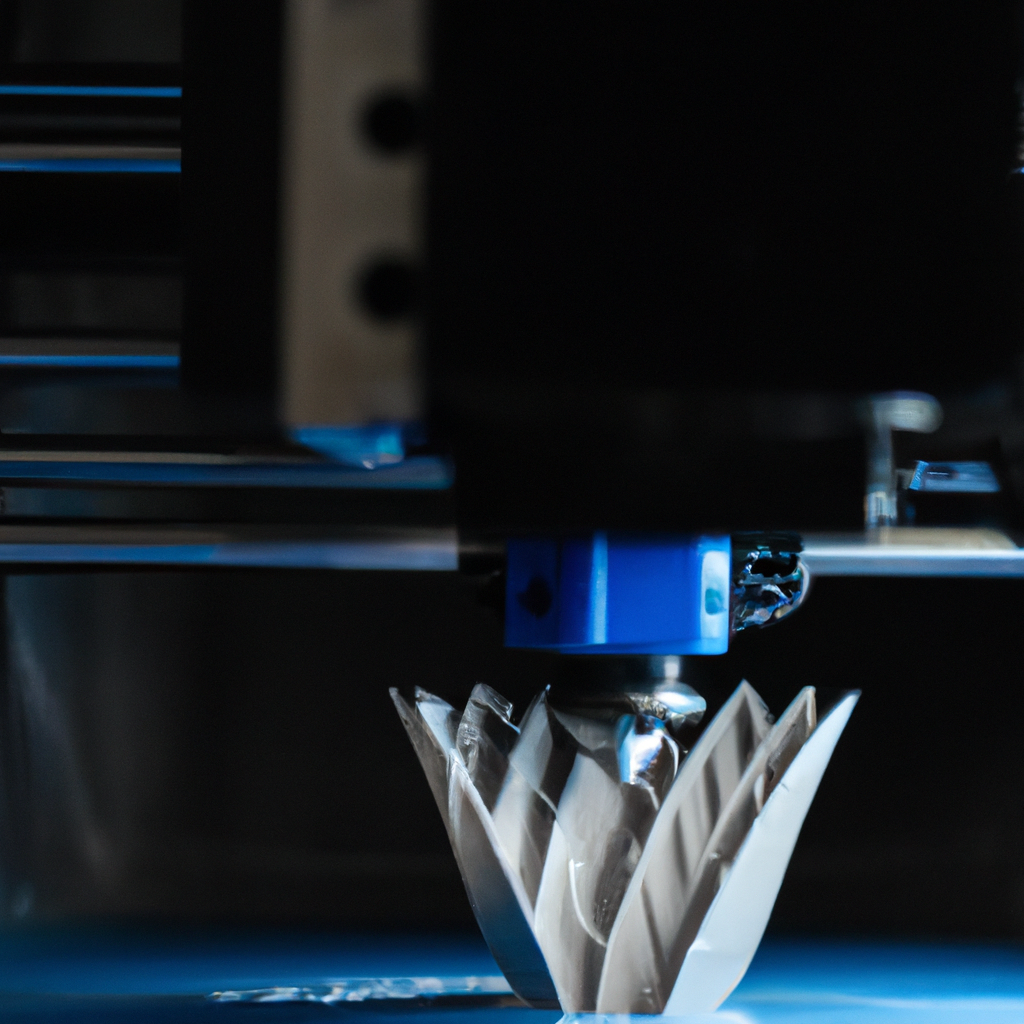

In a rapidly evolving manufacturing landscape, staying ahead of the competition requires innovation and adaptation. Additive Manufacturing (AM), often referred to as 3D printing, has emerged as a transformative technology that holds immense potential for businesses. In this article, we’ll explore how AM is revolutionising manufacturing in Cambridgeshire and delve into the remarkable benefits it brings to the table.

Embracing Change for Business Success

Companies in Cambridgeshire have an opportunity to reconfigure their manufacturing processes with Additive Manufacturing. This set of cutting-edge technologies has already proven its worth by enabling businesses to achieve:

Cost Savings and Efficiency

Additive Manufacturing provides the power to reduce production costs and minimise waste. By producing exact quantities required for each job or specific customer, businesses can significantly cut down on excess inventory. Not only does this save resources, but it can have a healthy effect on the bottom line.

Design Flexibility and Innovation

Traditional manufacturing methods often come with limitations when it comes to intricate designs. Additive Manufacturing can significantly reduce, or even eliminate, these constraints, allowing for the creation of complex designs without the need for costly machining operations or specialised tooling. The newfound design flexibility has already sparked innovation across many industries.

Rapid Prototyping and Faster Iteration

The speed of product development cycles is crucial for staying competitive. Additive Manufacturing’s rapid prototyping capabilities enable businesses to iterate designs quickly and efficiently. This acceleration, coupled with mass customization, empowers businesses to refine their products and ideas at an unprecedented pace.

Streamlined Supply Chain

Cambridgeshire’s vibrant manufacturing ecosystem can gain a competitive edge through AM. Manufacturing smaller quantities becomes economically viable, reducing the reliance on expensive tooling and lengthy CAD-CAM operations. This streamlined supply chain can catalyse growth and agility, as well enable alignment with other industry trends towards achieving net-zero.

Environmental Impact and Sustainability

Beyond its economic advantages, Additive Manufacturing contributes to sustainability efforts. Novel metal technologies, like Cold Spray and Wire-based AM, can efficiently utilise certified recycled alloys, saving resources and reducing the environmental footprint of manufacturing processes.

Overcoming Challenges through Expertise

Adopting Additive Manufacturing can be daunting, especially in the case of metal 3D printing. The key lies in seeking expert guidance. Organisations like M A M Solutions working together with the Smart Manufacturing Alliance can offer a tailored introduction to AM specifically designed for companies in and around Cambridgeshire. Funding support may also be available to alleviate initial costs.

The dawn of Additive Manufacturing could mark a transformative era for manufacturing companies in Cambridgeshire. The benefits are vast and undeniable: cost savings, design innovation, rapid prototyping, streamlined supply chains, and environmental consciousness. Embracing this technology is not just a leap forward but a strategic move toward sustained success.

Written by SMA Corporate Partner – Dr. Martin McMahon – M A M Solutions – M A M Solutions – Tailored Additive Manufacturing Solutions

Find out more here:

https://www.sma-uk.co.uk/wp-content/uploads/2023/08/AM-Flyer-March-2023-final.pdf

Ready to take the next step?

Contact tracy.grazioli@opportunitypeterborough.co.uk