Cambridgeshire – Peterborough manufacturing supply chain to benefit from new partnership

International, industry-based research and technology organisation (RTO) TWI Ltd, which has its headquarters in Cambridge, and the Smart Manufacturing Alliance, which works across Cambridgeshire and Peterborough, have formed a new partnership to help manufacturers and their supply chains optimise market opportunities for business optimisation.

The last couple of years have seen the UK’s manufacturing industry needing to face a number of challenging situations such as the COVID-19 pandemic, the country’s withdrawal from the EU, potential skills shortages and supply chain disruption. In addition, companies need to look to the future and be able to address key changes in the wider operating environment proactively, and with strategies and activities that support this.

It was with these factors, and more, in mind that led TWI’s Innovation Network and the Smart Manufacturing Alliance to join forces, and move forward with a new partnership to support the Cambridgeshire – Peterborough manufacturing community.

The Smart Manufacturing Alliance aims to develop a world-class manufacturing cluster across Greater Cambridgeshire and Peterborough, a region which is home to over 3,000 manufacturers specialising in everything from 3D printing and pharmaceuticals through to engines and robotics, so that every manufacturer in the region can reach their full potential. Members have access to a network of like-minded manufacturers, supported by its team’s connections to relevant experts within industry, and across technology development, finance, education and academia.

The TWI Innovation Network (TWIIN) offers its associates, partners and Subscriber companies support with unlocking innovation through the leveraging of public funding through collaborative working, as well as with dedicated services. This sees TWI’s Technology Innovation Management (TIM) team, Innovation Centres (strategic industry-academic partnerships) and technology specialists working closely with SMEs, larger companies and RTOs – to form consortia of innovators with complementary knowledge and capabilities who together can submit proposals for engineering-technology R&D – to attract public funding from programmes such as Horizon Europe and Innovate UK.

Both the Alliance and TWIIN also run annual events programmes at which attendees are able to network and extend their contacts, meet the people most suited to assist their business, and learn about recent developments in manufacturing and associated industries.

Tat-Hean Gan, TWI’s Director of Research and Innovation, said “Some of the most pertinent subjects for manufacturers to address now, and in the coming years, are the drive towards net zero operations, adapting to industry 4.0 developments, and the transition to smart factories and automation. Therefore, TWI’s Innovation Centres for, respectively, Joining 4.0, Circular Economy and Recycling, Industrial Decarbonisation and Hydrogen, Industrial Net Zero, Renewable Energy, and Artificial Intelligence, together with TWI’s technical sections, TIM team and extensive networks, are ideally placed to support the Smart Manufacturing Alliance, with its aims for the regions manufacturing supply chain members. We look forward to this new partnership and the avenues it can open up for everyone concerned.”

Bob Hart, Programme Director of the Smart Manufacturing Alliance, said “One of our top priorities is to encourage higher levels of innovation among Cambridgeshire and Peterborough manufacturers. With such a heavy concentration of manufacturers and broad range of specialisms across the region, it’s imperative that we bolster their R&D and new product development to ensure our manufacturing sector can compete at a global level. TWI’s Innovation Centres, TIM team, and technical sections are a huge asset to our region and we’re very excited about the potential our new partnership is creating for our members.”

So what types of innovation will this partnership support?

Examples from our members:

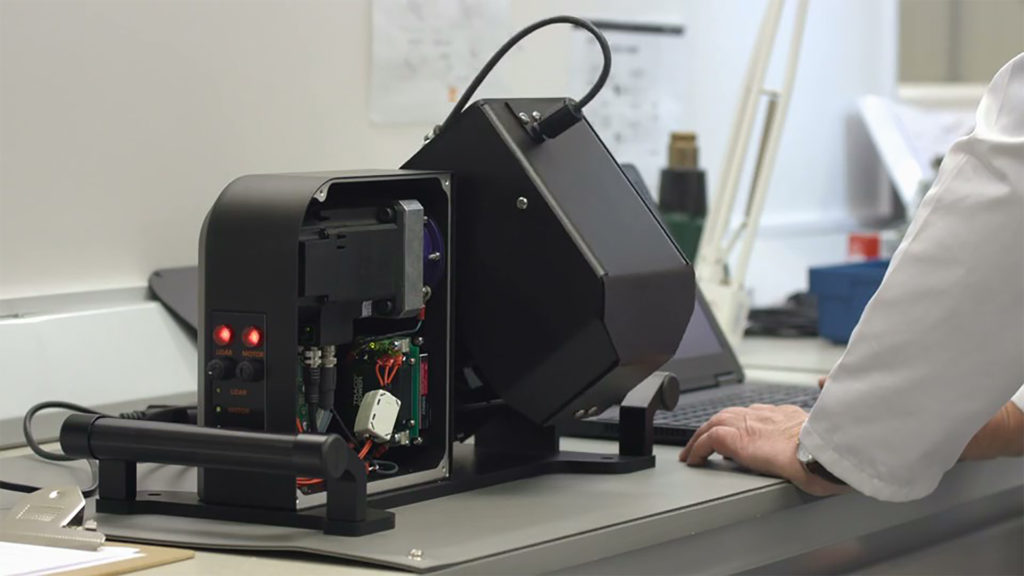

- PCML – 3D Imaging

PCMLGroup specialise in the precision engineering and manufacture of custom-built parts and components for use in medical, biotech, scientific and industrial technologies.

PCML recently partnered with a UK 3D Mobile Mapping Company to manufacture and build the precision parts and bespoke components for one of their 3D imaging cameras, used to map changes within difficult to reach places, such as mines and caves. PCML Group manage the complete design for manufacture, production, and assembly for all the required parts and looms –with full control of the BOM, manufacturing process and supply chain

Partnering with our clients at the early design stages and working in collaboration with specialist design consultants – ensures the smooth delivery of products through our entire manufacturing, quality, test, and assembly process.

2. Xaar – Ultra High Viscosity Printing

Xaar’s Ultra High Viscosity Technology can ‘print without limits and drive creativity” according to a new white paper. Its printheads have reached a new level of precision and can deposit more fluids at ambient temperature, taking the inkjet 3D printing or coating of parts to a whole new level. For more on Xaar’s high viscosity printing, visit: https://3dprintingindustry.com/news/xaar-pushes-the-boundaries-of-inkjet-technology-with-ultra-high-viscosity-printing-200836/